Student awards 2022

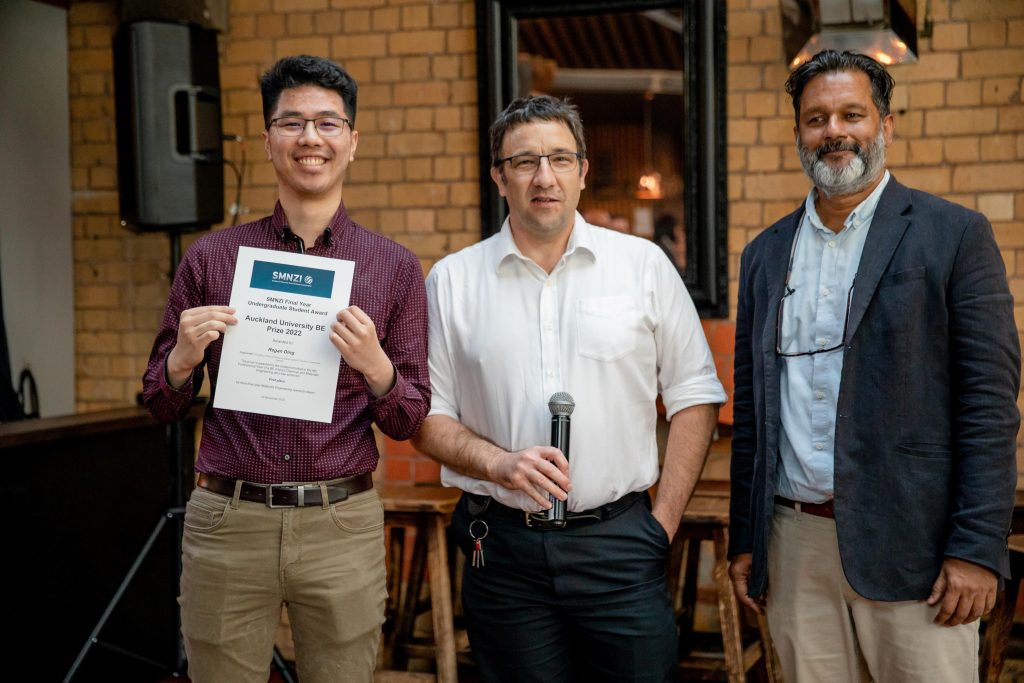

SMNZI award winners 2022

First Place: Regan Ding

Project Title: The effect of heat treatment on plasma sprayed Titanium Carbonitride coatings

Second Place: Juliet Shepherd

Project Title: The Optimization of Block Copolymer Self-assembly

Abstract for first place:

ABSTRACT

Thermal spray is a relatively new technique for applying wear-resistant coatings, and TiCN-based cermets have become of interest due to the relative abundance of raw materials. Thermal spray often results in the dissolution of the carbide/nitride phases from high temperatures resulting in brittle supersaturated phases. This work takes a novel approach by maximising dissolution through a high-temperature plasma spray and utilising heat treatment to reprecipitate nano-sized carbides and nitrides to form a true nano-sized cemented carbide. No shroud and Ar-shrouded TiC30N70-6Mo2C-29Ni coatings were plasma sprayed and characterised using XRD and SEM/EDS, and the coatings were heat-treated at critical temperatures determined from DSC. The feedstock powder was also characterised. The feedstock powder showed the formation of MoC and minor dissolution of TiCN. MoC is assumed to form from the precipitation of Mo into a C-rich environment left by the dissolution of Ti. The AS coatings showed high but incomplete dissolution of the carbonitride phase, likely due to the relatively high melting temperature of TiCN. Only one critical temperature was identified at 1030oC in the no-shroud coating; it was assumed that the lack of critical temperatures was from constant chemical/physical changes occurring throughout temperatures due to the complex composition and microstructure of the coatings. The coatings were heat treated for 45 mins under 99.9% Ar environment at 750oC, 1050oC and 1200oC. The heat-treated coatings showed nano-sized reprecipitation of TiCN starts between ambient and 750oC; however, above 750oC, these precipitates quickly oxidised into TiO2 due to their high surface area to volume ratio. Mo was also found to dissolve into the Ni binder as TiCN precipitated. Heat treatment temperatures at and above 1050oC showed rapid oxidation, with near complete oxidisation of TiCN at 1200oC. The core-rim structure often seen in TiCN-Mo-Ni-based cermets did not form due to the lack of liquid-phase sintering. Future work recommends higher sintering temperatures, lower heat treatment temperatures for longer times, reduced powder feed rate during spray, and using purer Ar gas.

Abstract for second place:

ABSTRACT

Block copolymers’ ability to self-assemble into distinct nanostructures makes them desirable for advanced micro and nano applications. Solvent vapour annealing is one method to reach short- or long-range order in polymer films, to reduce annealing times dynamic methods have been investigated. Dynamic solvent vapour annealing was performed on cylinder forming PS-b-PVP using THF and PS-b-PEO using benzene and water. A nitrogen carrier gas flow rate of 8.7 ml/min successfully created films with 100% perpendicular cylinder orientation, clearly showing improvement over unannealed and statically annealed samples within one hour. Heating the solvent was found to get PS-b-PEO films closer to short-range order within the same time frame. Significant height variations were found on the statically annealed PS-b-PVP films and was thought to be caused by water vapour contamination, domain spacing, or elevated temperatures. Crystallisation was found to occur on all annealed PS-b-PEO films, increasing in size or number as a result of greater benzene absorption, without hindering the annealing effects on the nanodomains. More work is still to be done in order to find the optimal annealing conditions for both polymer systems as the maximum annealing time, influence of water, and ideal residence time has yet to be realised.